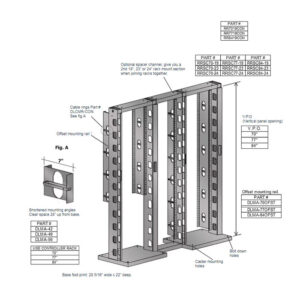

Features:

Our four-post rack with advanced cable management capabilities for servers, networking and telecom applications features an open design that allows easy access to all your equipment.

It’s available in either a 19” or 23” rack mount and is made of 12 gauge steel with a 5/16” base.

With a weight capacity 2,200 lbs. it’s a cost efficient alternative to cabinets.

This unit adjusts from a 26” to a 42” depth and is available with universal mounting holes or tapped 10/32 holes. Individual racks can be bolted together and can be mounted to the floor.

It comes supplied with 40 cage nuts and screws with easy assembly instructions.

Cable managers are available.

To order:

Add the suffix “T” at the end of the part number for tapped holes and “S” for square holes. e.g. A4P77-19S